INNOVATION

MATERIALS

In a world that changes faster than ever, the constant search for materials with superior performance and a commitment to give innovative solutions to industrial architects and designers have led to the discovery of new materials: titanium, magnesium and other metals. The systems we use for 3D scanning ensure unrivalled accuracy in dimensions, thicknesses and surfaces. Deep drawing simulation software allows us to analyse any critical issues before designing the dies.

TECHNOLOGY

The improvement of technologies and the search for new product development methods are the key factors in the evolution. It is precisely the improvement of traditional technologies, namely deep drawing or cold deformation of sheet metal, that precedes the development of new technologies such as the processing of magnesium and titanium as well as the cutting and laser processing of ferrous and non-ferrous materials. The sum of such knowledge, made available to the customers, creates technological opportunities to be seized in a market that is constantly looking for new production solutions.

PARTNERS

The purpose of the collaboration with the University of Padua is to develop excellent skills in the field of laser processing and metallurgical processes. The active search for new materials to be used with our customers finds a natural partner in the university: together, we are investigating fields that are yet to be explored.

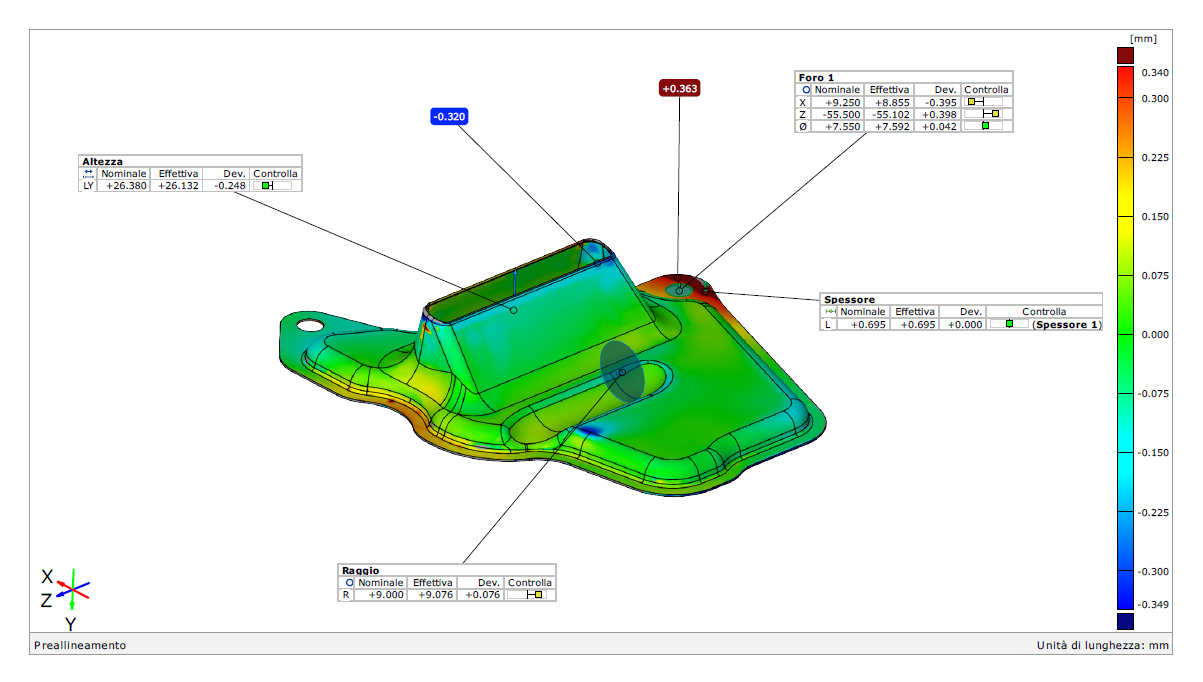

REVERSE ENGINEERING

Through the use of structured light we are able to perform 3D “contactless” precision detections.

Starting from a physical component it becomes thus possible to obtain a .stl file, a precise dimensional report or to reconstruct an accurate calculation in a format that is compatible with the most common 3D software.